ROLL SELECTION OF MATERIAL FOR VARIOUS TYPE OF ROLLING MILLS

Silvan Rolls, as a result of the work we have done with deep experience and knowledge of years, we have a roll quality selection table that we believe to help the rolling mills who are our main customers to choose the sphero and steel-based roll qualities in our product range for use in various rolling stands of various types of rolling mills. Our customers, to whom we supply rolls in domestic market and abroad, choose the most optimum roll quality for their production by making use of our roll selection table in the roughing, intermediate and finishing stands in bar mills and light and medium profile rolling mills. First of all, it is necessary to talk about the Silvan Rolls’ auality of tolls, which are the subject of the roll quality selection table. Silvan Rolls performs roll casting in two main groups: nodular graphite and steel-based. Steel-based rollers are divided into two as Adamite and Graphitic Steel. Nodular Graphite Sphero Rolls are divided into two as Acicular Sphero and Perlitic Sphero. Brief information about these quality groups is given below.

STEEL BASE ADAMITE CAST ROLLS

Graphitic steel rolls include carbide and spherolite within the pearlitic matrix of their structure. In working conditions where high reduction ratios exist, our graphitic steel quality meets the requirements of light and medium section mills because of its high resistance against breakage and wear. Rolls of this quality are also subjected to heat treatment after casting to provide the best microstructure and mechanical properties for rolling conditions.

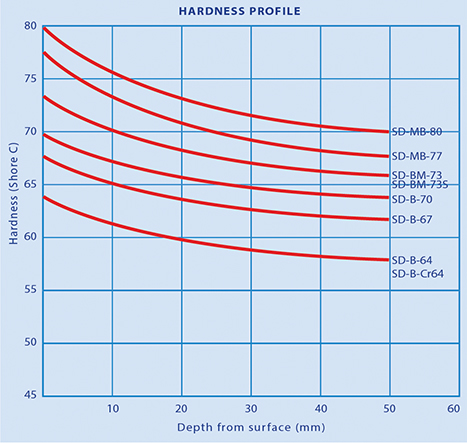

Hardness profile of Steel Base Adamite Materials

GRAPHITIC STEEL CAST ROLLS

Graphitic steel rolls include carbide and spherolite within the pearlitic matrix of their structure. In working conditions where high reduction ratios exist, our graphitic steel quality meets the requirements of light and medium section mills because of its high resistance against breakage and wear. Rolls of this quality are also subjected to heat treatment after casting to provide the best microstructure and mechanical properties for rolling conditions.

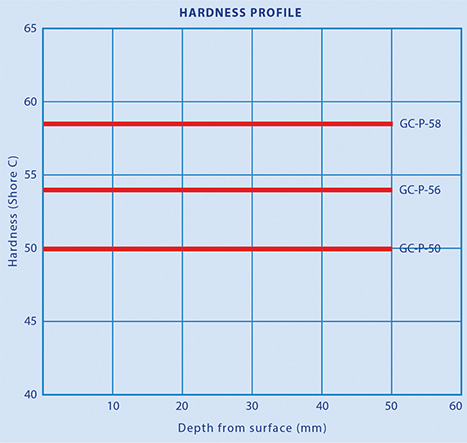

Hardness profile of Graphitic Steel Materials

NODULAR GRAPHITE (PEARLITIC SPHERO) ROLLS

Nodular graphite cast iron rolls are produced from alloy cast iron with spheroidal graphite material that has high resistance to wear. Softer grades of these rolls are more resistant to heat cracks and harder ones resistant to wear. As a result of our research and studies, we have developed solutions for the problems like sharp hardness falls, minimization of heat cracks due to thermal shocks and keeping the roll life decline at minimum levels in cases where welding is unavoidable.

In addition, our high alloyed ‘Mo’ rolls subjected to a special heat treatment process enable constant hardness from surface to the core of the rolls. This superiority provides strength against heat cracks and breakages.

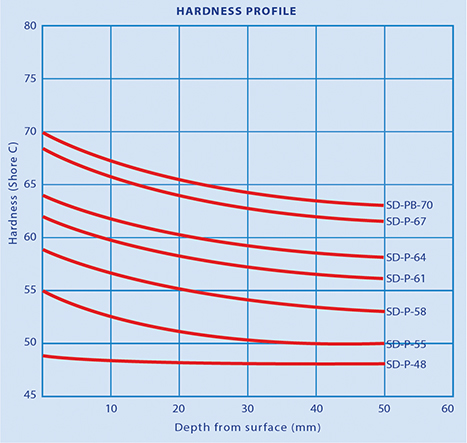

Hardness profile of Pearlitic Sphero Materials

NODULAR GRAPHITE (ACICULAR SPHERO) ROLLS

Acicular sphero rolls are produced from high alloy spheroidal graphite cast iron material. After casting, these rolls are treated through After casting, these rolls are treated through process which is primarily applied for the purpose of relieving the internal stresses, as well as to ensure the complete transformation of possibly retained austenitic phase in the microstructure.

This microstructure named as acicular structure is obtained through formation of bainitic and needle structured martensitic carbides.

The demand for special quality of rolls with resistance to thermal shocks and wear, required for slitting systems which have now wider use in rolling mills are met with SD-BM- 73S quality.

Hardness profile of Acicular Sphero Materials